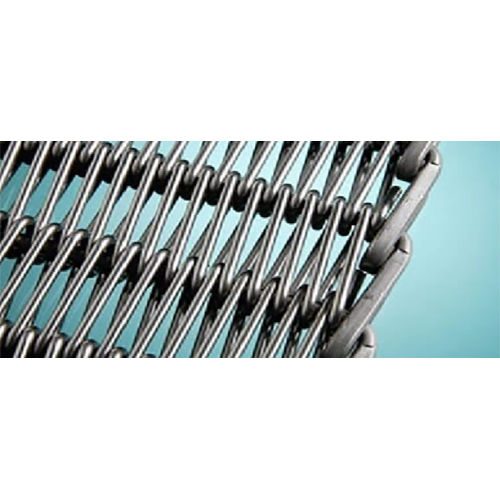

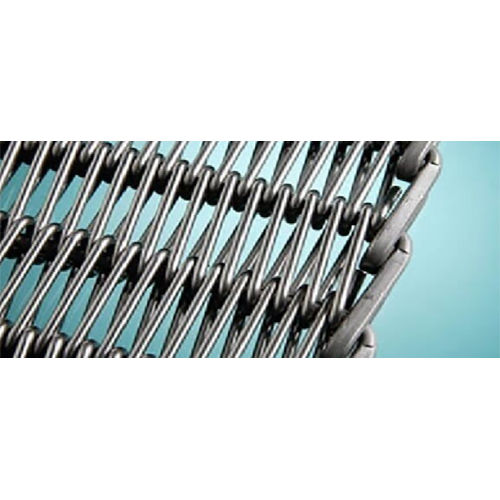

Round Wire Spirals

Product Details:

- Features High strength, flexibility, easy installation and cleaning, long service life

- Thickness 1mm to 3mm (as per requirement)

- Surface Finish Smooth, bright finish

- Belt Type Round wire spiral belt

- Power Source Manual or motorized (based on installation)

- Material High-quality Stainless Steel / Carbon Steel

- Type Round Wire Spiral

- Click to View more

X

Round Wire Spirals Product Specifications

- Spiral wire structure

- Round Wire Spiral

- High strength, flexibility, easy installation and cleaning, long service life

- Food processing, baking, drying, cooling, packaging, and other industrial conveyor applications

- 1mm to 3mm (as per requirement)

- Varies by design and usage

- Customizable as per application requirements

- Smooth, bright finish

- Corrosion and abrasion resistant

- High-quality Stainless Steel / Carbon Steel

- Compatible with belt conveyors

- Not compatible

- Round wire spiral belt

- Manual or motorized (based on installation)

Product Description

Radius conveyor belt also known balanced wave belt because if composed of balanced weaved spiral mesh, straight cross rods and chain links on both sides. They are suitable for a wide range of applications, constructions and process conditions throughout the world. Radius belts offer a smooth continuous product flow running dependably year after year without damaging fragile and delicate products.

Features:

- Stable design for smoothly, dependably and gentle movements.

- Money saving by securing the quality of products and reducing waste.

- Close-structure structure and ideal for high tensile load.

- Suitable for radius system, spiral, curved or straight conveyors.

- Wide temperature range from -196 Degree C to +275 Degree C

- Complying with FDA standards.

Applications:

- Food cryogenic cooling and freezing.

- Vegetable blanching.

- Dough proofing.

- Drying installations.

- Product lifting conveyors.

- Baking or pasteurizing systems.

- Conveyor machines.

- Ovens, froster, annealing furnaces.

- Frying, refrigeration and cleaning facilities.

Engineered Versatility for Every Industry

Round Wire Spiral belts are designed to meet the diverse needs of industries such as food processing, metallurgy, electronics, and more. With customizable dimensions, mesh sizes, and edge types, these belts can be tailored for precise requirements, ensuring optimal performance in each unique application.

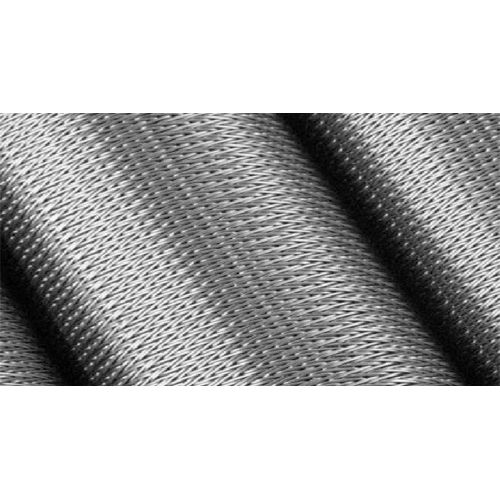

Superior Durability and Performance

Manufactured from high-quality stainless or carbon steel, round wire spirals offer exceptional strength, flexibility, and resistance to corrosion and abrasion. Their reliable construction ensures longevity and ease of maintenance, making them suitable for high-load, high-temperature, or continuous processing environments.

Seamless Installation and Maintenance

Delivered pre-assembled for immediate installation, these spiral belts reduce downtime and simplify integration into existing belt conveyor systems. Their smooth, bright finish facilitates efficient cleaning and hygiene-critical for food and pharmaceutical industries-while their design supports easy routine maintenance.

FAQ's of Round Wire Spirals:

Q: How is the width of the Round Wire Spiral belt customized to fit my application?

A: The belt width can be tailored from 200mm to 2000mm to suit your conveyor system's requirements. You can specify your desired width during the ordering process to ensure a precise fit for your industrial setup.Q: What edge types are available and how do I choose the right one?

A: Round Wire Spiral belts are available with welded, chain-linked, or selvage edges. The choice depends on your application's load, edge durability, and conveyor design. For heavy loads, welded or chain-linked edges provide enhanced strength, while selvage edges are suitable for lighter, less abrasive tasks.Q: Where can these spiral belts be used effectively?

A: These belts find effective applications in food processing (like baking and dairy), chemical, electronics, ceramics, glass, metallurgy, and various other manufacturing environments where flexibility, durability, and hygiene are essential.Q: What operating temperature range can these belts withstand?

A: Depending on the material, Round Wire Spiral belts can function efficiently within a wide temperature range, from -40C up to 1200C, making them suitable for extreme cold or high-heat processes.Q: How does the installation process work for these belts?

A: Belts are supplied pre-assembled and ready for installation, significantly minimizing setup time. They are compatible with belt conveyors but are not suited to roller conveyors. Installation can be manual or motorized, depending on your facility's requirements.Q: What are the key benefits of using this type of conveyor belt?

A: Key advantages include high strength, excellent flexibility, corrosion and abrasion resistance, easy cleaning, minimal maintenance, and long service life-making them ideal for demanding industrial and food-grade environments.Q: How do I select the appropriate mesh size and open area?

A: Mesh size (from 2x2mm to 50x50mm) and open area (30% to 85%) are chosen based on your application's need for product support, airflow, or drainage. Discussing your process requirements with a distributor or supplier will help you select the best configuration.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email