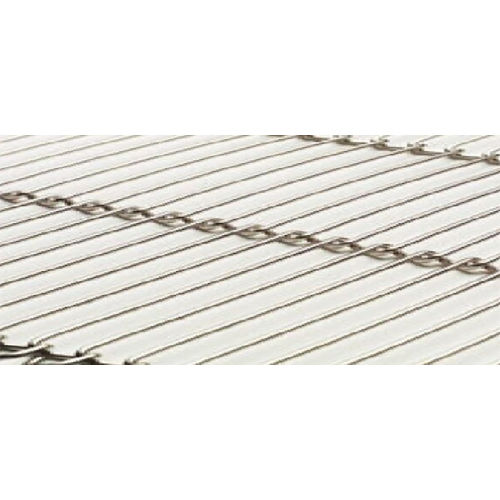

Rod Network Belt

Product Details:

- Thickness 2.0 mm - 5.0 mm

- Power Source Mechanical Drive

- Surface Finish Polished

- Belt Type Rod Mesh Belt

- Features High Strength, Low Maintenance, Durable, Long Life

- Material Stainless Steel

- Type Rod Network Belt

- Click to View more

X

Rod Network Belt Product Specifications

- No

- No

- Stainless Steel

- Mechanical Drive

- 2.0 mm - 5.0 mm

- No

- Rod Network Belt

- Food Processing, Baking, Cooling, Freezing, Drying, Packaging Lines

- High Strength, Low Maintenance, Durable, Long Life

- Corrosion Resistant

- Modular Mesh

- Customizable as per application

- Up to 500 kg/m

- Yes

- Rod Mesh Belt

- Polished

Product Description

Rod network belts, also known as enrober conveyor belts or flat flex conveyor belts, feature specially designed Z-bend joints in the wire mesh. They are perfect for transporting light and medium weight products in food processing industries.

Features:

- High open structure - high proportion of open area up to 86% makes the belt efficient in cooling, drying, heating applications.

- Positive drive without slipping - Rod network belts are normally driven by sprockets positively without need for complicated tracking mechanisms.

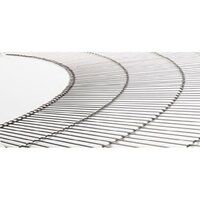

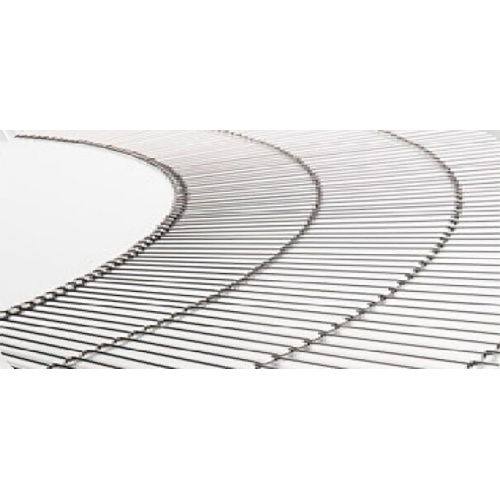

- Stable conveying - With smallest diameter end rolls and drive rolls, the rod network belts provide stable conveying of delicate products.

- A wide range of sizes - Various sizes with different openness to suit different applications providing superb strength and min contact surface between the and the belts. Generally, the more the joints cross the width, the stronger the belt.

- Lower belt mass - low belt mass than balanced weave belts for lower power consumption, faster processing and more product throughput.

- Cost saving - The high open structure without hidden crevices makes the belt easy to clean and maintain which result in considerable cost saving.

Details:

- Materials: quality spring steel AIS! 1060; stainless steel wire 302, K2930 or Custom others.

- Open area: 67.5% to 86%

- Wire diameter: 0.035" to 0.11" as your request.

- Pitch: 1/8" to 3/4" or custom others.

- Belt width: 3" fo 14' or custom width as your request.

Versatile Temperature Performance

Designed for extreme conditions, the Rod Network Belt offers reliable operation from -40C up to +500C, making it suitable for both high-heat baking and low-temperature freezing applications. This allows you to use a single solution for a wide variety of challenging environments, enhancing process flexibility and reducing system complexities.

Robust Modular Construction

With choices of welded or chain-linked edges and a polished stainless steel finish, the modular mesh structure of the belt ensures stability and easy cleaning. Its customizable width and pitch adapt to numerous conveyor systems, making integration seamless across food, pharmaceutical, metallurgy, and electronics industries.

FAQ's of Rod Network Belt:

Q: How do I select the right belt width and pitch for my application?

A: The appropriate width (200 mm to 3000 mm) and pitch (12.7 mm to 25.4 mm) depend on your conveyor's dimensions and the size of products you need to transport. You should also consider the load capacity, ensuring it matches your operational requirements. Our team can assist in tailoring the specifications to fit your particular process.Q: What industries commonly utilize the Rod Network Belt?

A: This belt is widely used in food processing, pharmaceutical manufacturing, metallurgy, and electronics assembly for applications such as baking, cooling, freezing, drying, and packaging due to its durability and hygienic stainless steel construction.Q: When should I choose the welded edge over the chain-linked edge type?

A: Welded edges are ideal for straightforward conveying tasks and offer increased simplicity and strength, while chain-linked edges are recommended if you need precise belt tracking or higher lateral stability on the conveyor.Q: Where can the Rod Network Belt be installed?

A: It is designed for mechanical belt conveyor systems found in production lines within factories, processing plants, and packaging facilities. This belt is not suitable for vertical or pneumatic conveyors.Q: What is the process for maintaining the Rod Network Belt?

A: Maintenance is minimal due to the corrosion-resistant, polished stainless steel build. Regularly inspect for wear, keep the surface clean, and ensure the mechanical drive is functioning smoothly to maximize operational lifespan.Q: How does the Rod Network Belt benefit operational efficiency?

A: Its high strength, customizable speed, low maintenance needs, and long service life minimize downtime and replacement costs. The belt's capability to handle up to 500 kg/m2 ensures smooth, reliable handling even for heavy-duty processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email