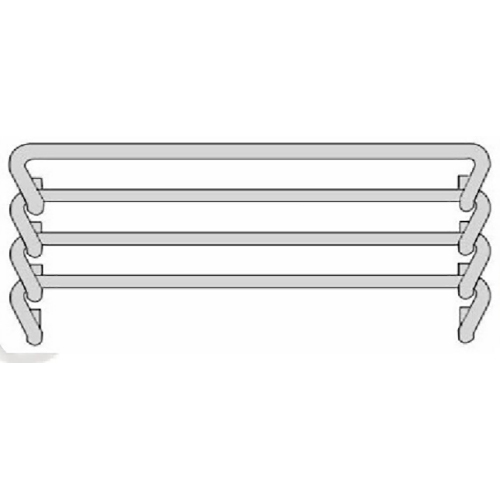

Ladder Conveyor Belt with S Shaped Hooks

Product Details:

- Belt Type Ladder-type wire belt

- Features Easy to clean, open mesh for air/water flow, positive drive, lightweight

- Power Source Mechanical or Motor Driven via external drive unit

- Surface Finish Smooth polished or as required

- Thickness Standard 1.5 mm to 5 mm (customizable)

- Material High-grade Stainless Steel or Mild Steel (as per requirement)

- Type Ladder Conveyor Belt with S Shaped Hooks

- Click to View more

X

Ladder Conveyor Belt with S Shaped Hooks Product Specifications

- Easy to clean, open mesh for air/water flow, positive drive, lightweight

- Open construction with ladder cross rods and S-shaped hook articulation

- No

- Ladder-type wire belt

- Smooth polished or as required

- Corrosion-resistant, heat-resistant, and abrasion-resistant

- Variable as per drive mechanism setup

- High-grade Stainless Steel or Mild Steel (as per requirement)

- Yes

- Mechanical or Motor Driven via external drive unit

- Food processing, baking, cooling, drying, freezing, part handling, and general material conveying

- Ladder Conveyor Belt with S Shaped Hooks

- Standard 1.5 mm to 5 mm (customizable)

- Not required (mechanical operation)

- Up to 1000 kg/m (customizable depending on application)

- Not required (mechanical operation)

Product Description

With the simplest structure, the ladder conveyor belts composed of cross rods jointed by S - shaped hooks, chain links and U - shaped links. The belts with links are secured by welding a ring to the cross rod for containing the integrity of the ladder conveyor belts.

Details:

- Material : steel, stainless steel 304, 316 or other materials as your request.

- Speed : from less than 1 m/min to 20 m/min. (High speed quick may affect the longevity of the conveyor belt

Application

- Food processing: cooling, washing, drying, etc.

- Waste treatment facilities.

- Product sieving and sorting system.

- Blanching and product handling system.

Specification

| Properties | Ladder belt with S-shaped hook | Ladder belt with chain links | Ladder belt with U-shaped links |

| Pitch | 1/2 to 4 | 1 to 3 | 3/4,1 and 1-1/13 |

| Width | 20 to 1500mm | 25mm to 2000mm | 80mm to 2000mm |

| Diameter of cross rod | 2 mm to 8mm | 4mm to 20 mm | 5mm |

| Application | Running in straight & curved application | Only running in straight application | Running in straight & curved application |

Customizable Design for Versatile Applications

This ladder conveyor belt can be tailored in size, material, pitch, and mesh design, accommodating a vast array of production requirements. Its flexibility in cross rod diameter and belt width makes it ideal for specialized tasks in food processing, freezing, drying, and part handling, ensuring efficiency across multiple industries.

Superior Durability and Compliance

Built from high-grade stainless or mild steel, the belt withstands rigorous operating conditions, from -50C to 400C, and supports loads up to 1000 kg/m2. With FDA-compliant materials, it is suitable for direct food contact, while its corrosion- and abrasion-resistant properties provide longevity even in harsh environments.

User-Friendly Installation and Maintenance

The open structure-with welded or S-shaped hooked edges-enables straightforward cleaning and rapid installation. Its low maintenance demands and simple tension adjustment make it ideal for operations seeking to minimize downtime and maximize productivity. Installation and after-sales services are available on request.

FAQ's of Ladder Conveyor Belt with S Shaped Hooks:

Q: How is the ladder conveyor belt with S-shaped hooks installed and maintained?

A: Installation is straightforward, with either welded or S-shaped hooked edges ensuring a secure fit. On request, professional installation services can be provided. Ongoing maintenance is minimal-routine checks and simple tension adjustments are all that's needed, thanks to its low-maintenance design and open structure.Q: What customization options are available for this conveyor belt?

A: You can customize the cross rod diameter (2 mm to 6 mm), pitch (12.7 mm to 50.8 mm), belt width (100 mm to 3000 mm), material (stainless steel or mild steel), and mesh design. Edge types and surface finishes are also modifiable to suit your unique application needs.Q: When should I choose a ladder conveyor belt with S-shaped hooks for my process?

A: Opt for this belt when you require excellent airflow, quick drainage, and consistent material transport in high- or low-temperature settings. It's especially valuable in food processing, baking, cooling, drying, freezing, and parts handling, thanks to its hygienic, easy-to-clean, and robust design.Q: Where can these conveyor belts be used effectively?

A: The ladder conveyor belt is widely used in food processing plants, bakeries, drying tunnels, freezing lines, and material-handling applications that demand sanitary and efficient conveying. It is suitable for operations requiring FDA-compliant and corrosion-resistant equipment.Q: What is the process for ordering a customized ladder conveyor belt?

A: Specify your required belt width, rod diameter, pitch, material, and any additional custom features. As a distributor, manufacturer, supplier, trader, and wholesaler in India, we support complete customization and can guide you through the selection to meet your operational demands.Q: How does the belt's open construction benefit usage and cleaning?

A: The open ladder-type design allows for optimal air and water flow, which is crucial for processes like drying, cooling, and baking. It also simplifies cleaning, making it easier to maintain sanitary conditions, especially in food-related applications.Q: What are the key advantages of using this ladder conveyor belt in an industrial setup?

A: Key benefits include high corrosion and heat resistance, versatile customization, easy cleaning, dependable FDA compliance for food safety, lightweight construction, and the ability to handle heavy loads with minimal maintenance requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email